Automatic transmissions have been undergoing a quiet evolution. Not only have the number of gear ratios increased, the way they are able to shift between gears has also changed.

Currently there are three types of automatic transmissions offered in vehicles. The CVT or Continuously Variable Transmission uses a belt-like chain and two variable width pulleys to provide the variable gear ratios. As the pulleys change width, the belt rides closer or further from the center of the pulleys, which changes the ratio and driving force. Vehicles with CVT gearboxes often have limited gear selections such as Drive and Low range, where each will allow the transmission to automatically adjust the gear ratios to the driving needs. Some CVT equipped vehicles also have a method of selecting several preset gear ratios, often through the use of paddle shifters on the steering wheel. All the shifting does is signal the computer to hold the pulleys in preset positions so it acts more like a conventional automatic transmission but still drives through the belt.

Another type of automatic transmission that is becoming increasingly popular is the DSG type transmission. There are several marketing names used for the DSG used in several makes, including Dual Shaft Gearbox, but they all operate on the same principle. There are two input shafts to the transmission, one inside the other. One input shaft drives the odd gears: 1,3,5 7 etc. and the other shaft drives the even gears: 2,4,6. Two clutch mechanisms are controlled by the computer, which also operates solenoids that shift the gears. When you place the transmission in Drive, the clutches are released but as you apply throttle, the computer automatically engages the clutch for the input shaft for 1st gear. As speed increases, the computer engages 2nd gear by releasing the 1st gear clutch and engaging the clutch for the 2nd gear shaft. To shift to 3rd, the same process occurs, with the clutch for the 1,3,5, 7 gear shaft being engaged again. The computer automatically shifts the gears in preparation for changing clutch drives so the gear shifts are smooth and very quick. DSG transmissions are basically computer-controlled manual transmissions and offer most of the efficiency of a manual transmission with the convenience of an automatic.

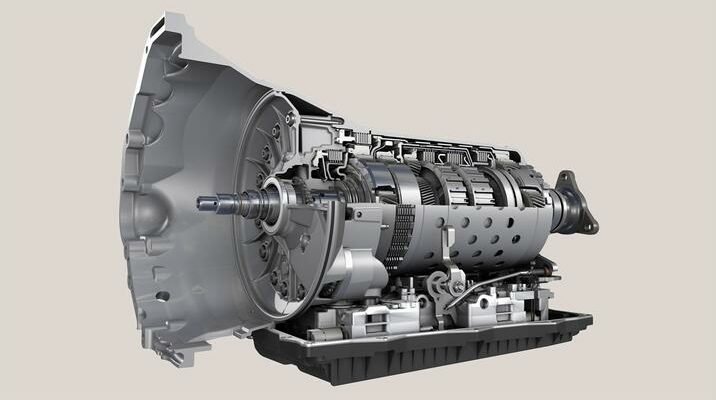

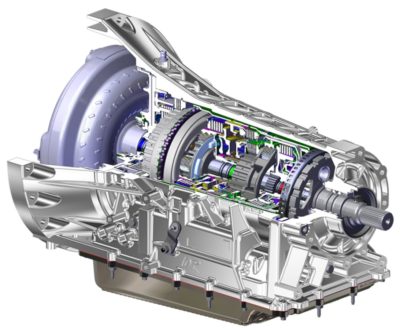

That leaves conventional automatic transmissions. These transmissions have been around for decades and some of the more common early models only had two gears. As transmission designs improved, the number of gears offered has increased. Three speed automatics were common in the 70’s. Four speed automatics became common in the 80’s and in this century 6 speed automatic transmissions have become common, although there are still some offered with 4 an 5 speed gearboxes. Recently, 7, 8 , 9 and even 10 speed automatic transmissions are being introduced. By having more gears in the transmission, the engineers are better able to tune the engine for optimum fuel economy in a narrower RPM range, yet still have gear ratios that will provide passing power or pulling torque when required.

Besides having more gears, the way the gears shift internally inside the transmission have also changed. It used to be common for the transmission to contain several one-way or overrunning engagement units called “roller clutches” or “sprags”. When you shifted to Drive range, a multiplate clutch with friction materials on it would be hydraulically applied and this would drive through a one-way clutch to the output shaft. When it was time to shift to the next gear, the transmission would apply another multiplate clutch and this would cause the one-way clutch to over-run or release mechanically. The shift was very smooth and only required one clutch to be applied. The same sequence would occur as 3rd and 4th gears were shifted into. During a downshift, only the multiplate clutch for that gear needed to be released and the one-way clutch would instantly engage mechanically.

The new transmission designs have almost eliminated one-way clutches however. They now use a Clutch to Clutch shift sequence, where shifting gears requires one multiplate clutch to release and another multiplate clutch to apply. Timing of these sequences is critical. Apply or release at the wrong time (and we are talking fractions of a second here) and you will either have an engine revving because nothing is engaged or a burned clutch because both are engaged at the same time!. Fortunately, the computer controls for modern transmissions have become very sophisticated and can control the shift timing accurately, even compensating for wear inside the transmission parts. They may be more complex, but they provide better performance and economy than ever.