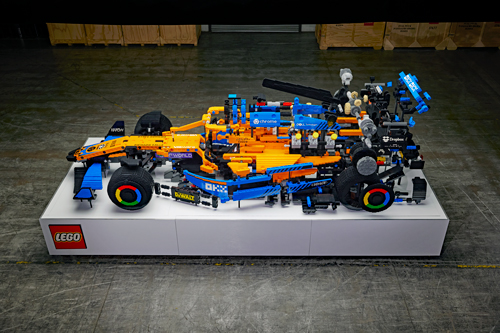

Fans at the Montreal Formula 1 race this year are able to interact with a stunning, life-size LEGO model of the McLaren car.

For the three days of the race event visitors have the chance to gawk at the model, constructed of 175,000 plastic parts at the “Under the hood” display in the Circuit Gilles-Villeneuve Parc Zone. They can also build their own little model of the car that was designed specifically for this event and take it home as a souvenir of their race weekend.

The race car build was managed by Greg Omartian, LEGO Model Designer, and Jeff Rushby, Senior LEGO Model Production Lead, both of LEGO Systems, Inc. In an interview they explained the details of the project and how the model actually shows technical design features of the car. It is eight times the size – bringing it to life size – of the LEGO Technic set that you can buy to build the McLaren model.

“The intention was to show how different components in the set come together to make the real components of the car,” Omartian said. The critical components are ‘exploded’ outward and secured using a system of rods and pins.

“The most interesting part of this one was the fact that it’s expanded to see all the parts, which when you’re designing and building a hundred different pieces, was the biggest challenge.

There are a lot of similarities with the F1 car, he noted. “There’s an engine block with a connecting rod and a piston. There’s a differential with three gears that mesh together with a bigger gear on the outside. There’s axles, there’s what look like disc brakes and rims and tires and connecting pins and things like that.”

The build took 2,000 hours, including design and construction, for a team of between two and seven people. It was designed and built at LEGO’s facility in Connecticut and shipped to Montreal in one piece, including the podium on which it’s mounted.

The timeline from concept to completion was only two months, Omartian recounted. And this build was notably different from others he’s done, as he was designing it in sections to speed up the overall build process. Starting at the front end, he created a section using LEGO’s proprietary software, then passed that on to Rushby’s build team. Then he moved on to design the next section while they built the first, and so on.

This unorthodox method did result in a few hiccups, the pair shared. With 18 different sections that had to be joined together there was the occasional moment when a builder would return to Greg noting there was nothing noted for a bolt connection or something was not symmetrical. “And I had to look at it again and say, ‘all right, hold off, let me fix that before you can keep building.’ With a lot of parts and different models within this display, it was hard to keep track of everything, but there weren’t too many of those moments.”

In fact, both designer and builder said they are really happy with the way the McLaren F1 model turned out. Omartian pointed out that in a way the short deadline was beneficial as otherwise the temptation exists to continue to tweak the design ad nauseum.

And for his part, Rushby said that while notes for improvement are usually shared by the build team with the designer, this time there were almost none. “I am happy with how this turned out. I think this was a very good project, a good collaboration between Greg and me and the rest of the team.”

The LEGO Group x McLaren racing experience will travel to races in Austin, TX and Mexico City later this year. After that Omartian and Rushby don’t know what the car’s future will hold.